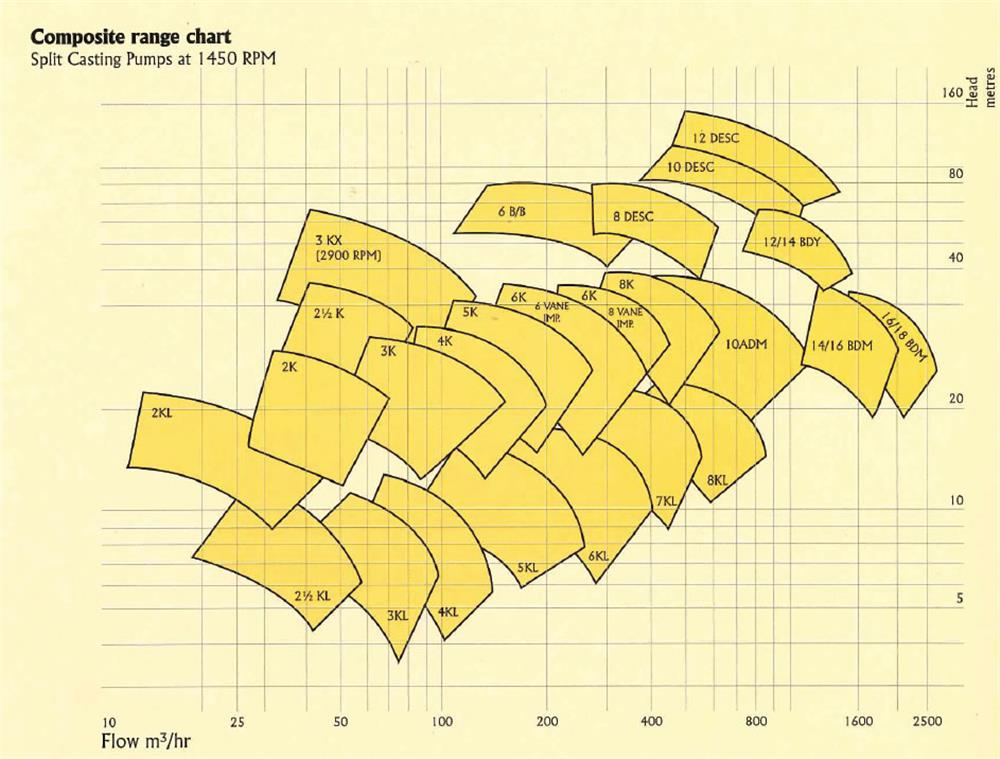

Split Casing Pumps

Applications

APE split case pumps are pratically maintenance free, and provide years of reliable, trouble-free service. These versatile pumps are available in a wide variety of materials and drivers, including electric motors, combustion engines and steam turbines to meet your application requirements.

General liquid pumping, power plants, steel mills, chemical plants, paper mills, refineries, cooling and heating systems and water booster service are few of the applications in which our split case pumps thrive.

Features

- Impellers are dynamically and hydraulically balanced, one-piece vauum cast of the Francis Vane deign. This reduces inlet losses and accommodates high suction lifts, which reduces axial thrust loads. Single suction impellers are mounted back-to-back for hydraulic balance, and their state-of-the-art contoured passegeways are extremely smooth, which results in high efficiency and quite operation. Impellers are firmly keyed and locked to an accurately finished oversized shaft to absorb all shock loads.

- The rugged, heavy duty two-piece casing is matched and split horizontally along the centerline of the shaft. This allows for removal of the rotating assembly without disturbing suction and discharge piping or the driver mounting. The lower half casing includes integrally cast mounting structure and a large volute-type suction area to assure laminar entrance velocities.

- Grease-lubricated cartridge-type bearings mounted in a rigid dust-proof housing support the rotating assembly, assuring smooth operation and extremely long bearing life.

- Large, deep packing boxes are carefully machined into the casing and come standard with packing and split interlocking gland. Most mechanical seals are interchangeable with packing box.

- Renewable casing and impeller wear rings are locked in place to prevent rotation. These rings are designed to minimize recirculation and maintain high efficiency over long periods.

- High-quality heat-treated steel shafts are accurately machined along their entire length with additional grinding to an even finer tolerance at the bearing locations.

- Easily replaceable centrifugally cast sleeves protect the shaft from packing wear, and are sealed to prevent leakage. Sleeves are accurately positioned and locked in place. Structural stell bases, designed to be filled with grout to lock the unit in place and provide mass to resist torsional movement, support the combined weight of the pump and driver.

Specifications

Casing

Cast iron volute type designed to produce a smooth flow with gradual change in velocity. It is split along the centre line, facilitating easy access to inspect or withdraw the rotating assembly wihout disturbing the pipe work.

Casting wear rings

All pumps fitted with easily replaceable wear rings.

Impeller

The impeller is of the shrouded double entry type, manufactured in bronze or cast iron. After machining the impeller is hand finished and statically balanced with the pump shaft to ensure smooth running of the rotating parts.

Shaft

The shaft is made of High-Tensile mild steel, turned and ground depending on the application.

Shaft Sleeve

Renewable shaft sleeve are fitted as standard to the D.E.S.C. range. Model K and KL can have these fitted as an extra.

Bearings

Model K and KL have self aligning ball bearings fitted. Model D.E.S.C. has heavy duty ball and roller bearings. All bearings are enclosed nd grease packed in housings bolted to the pump casing.

Stuffing Box

Stuffing boxes may be of the conventional soft packed type with adjustable glands arranged for either water or grease sealing. Alternatively, if preferred, mechanical seals can be fitted.

The materials mentioned in the specification are those supplied for pumps dealing with clean water. There is a choice of materials fr different applications.

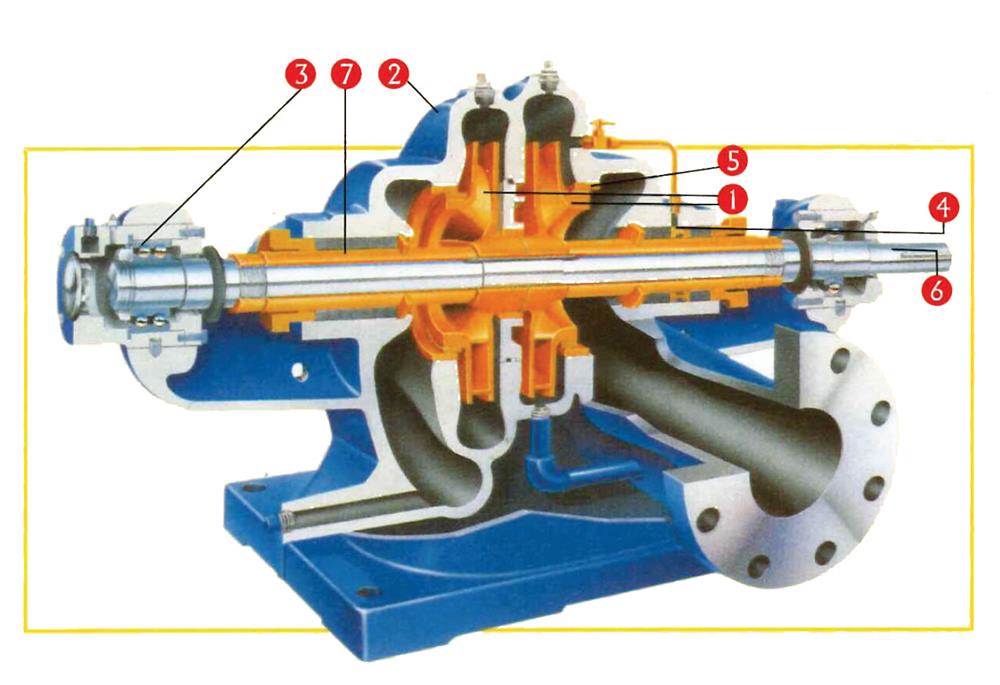

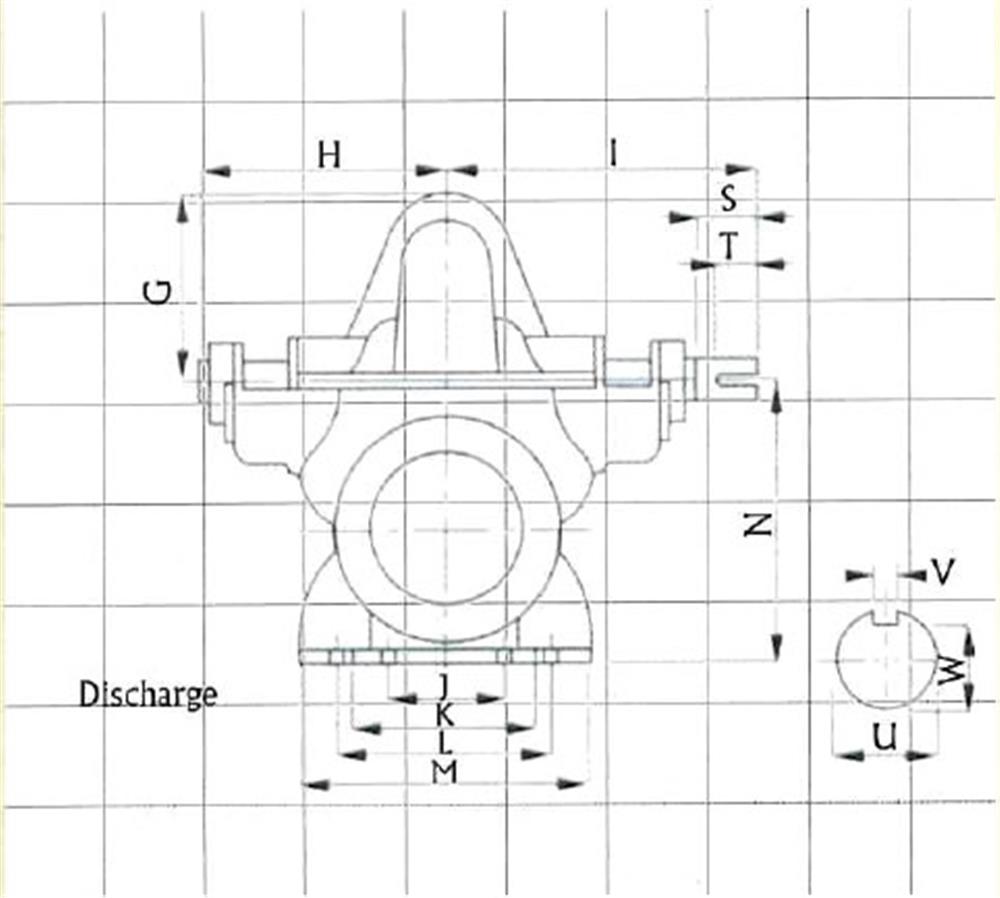

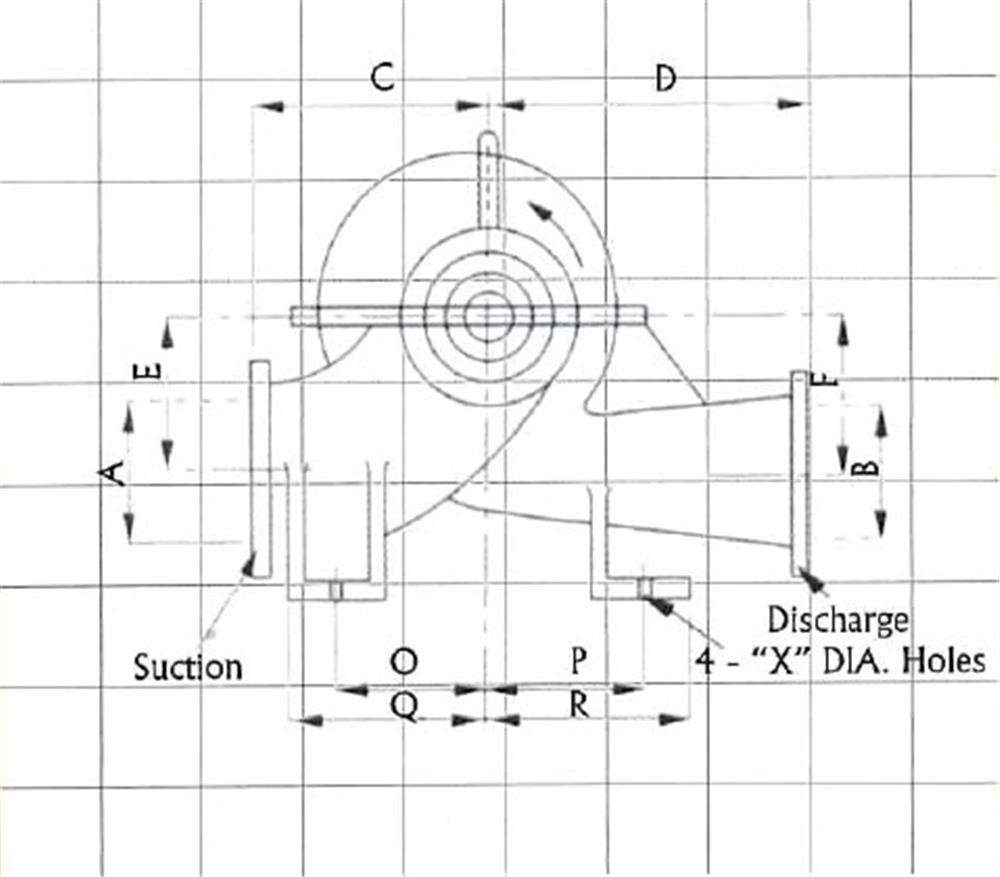

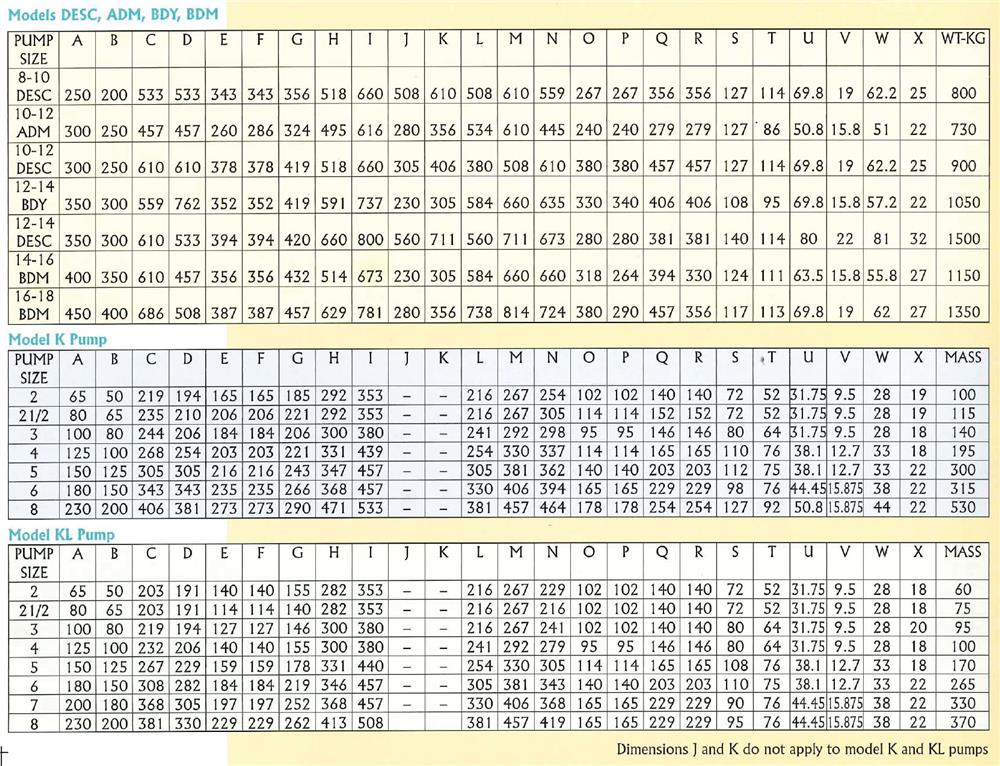

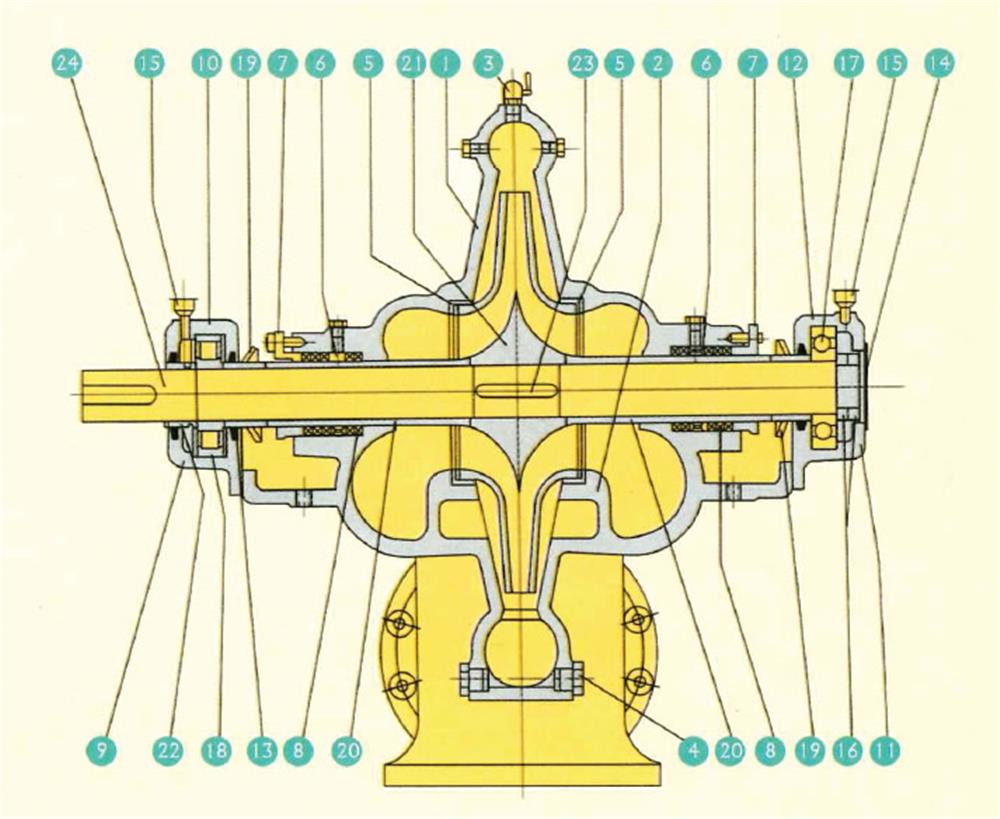

Section and Parts DESC, ADM, BDM, BDY Pumps

- Top Half Casting

- Bottom Half Casting

- Air Cock

- Drain Plug

- Casing Eye Ring

- Lantern Ring

- Gland

- Gland Packing

- D.E. Bearing Bracket

- D.E. Bearing Bracket Cap

- T.E. Bearing Bracket

- T.E. Bearing Bracket Cap

- Felt Washer

- T.E. End Cover

- Stauffer

- Shaft Nut

- Ball Bearing

- Roller Bearing

- Thrower

- Shaft Sleeve

- Impeller

- D.E. Shaft Nut

- Impeller Key

- Shaft

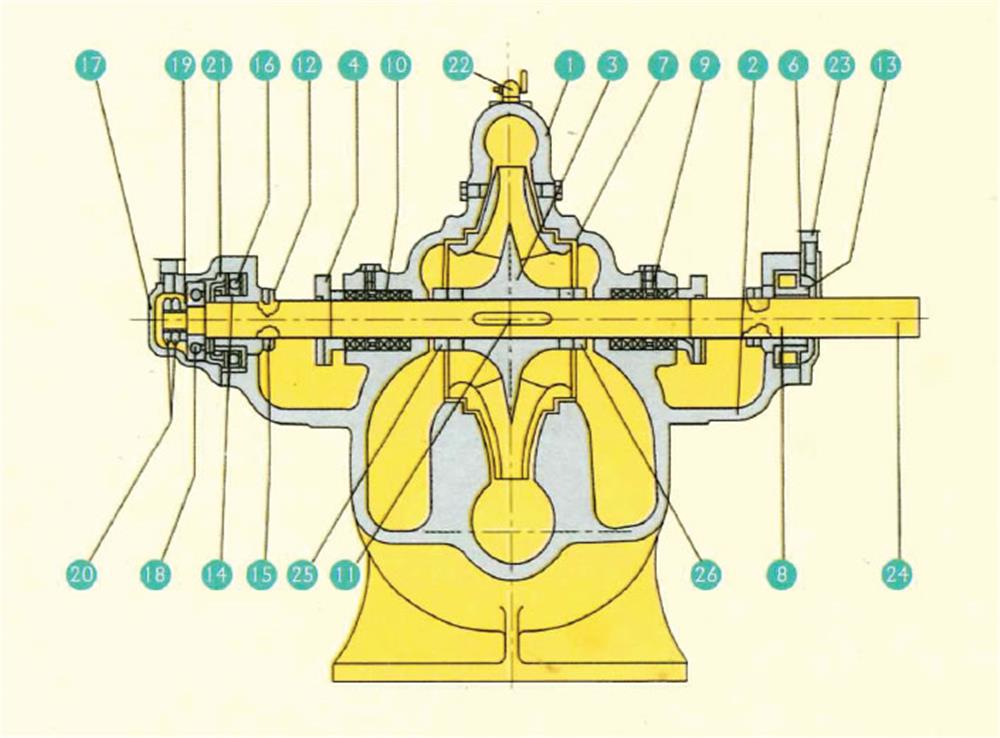

Section and Parts K and KL Pumps

- Top Half Casting

- Bottom Half Casting

- Impeller

- Glands

- Bearing Housing Caps

- D.E. Bearing Cover

- Casing Eye Rings

- Shaft

- Lantern Rings

- Gland Packing

- Impeller Key

- Bearing Sleeve

- Bearing Sleeve Nut

- Bearing Sleeve LCK. Washer.

- Bearing Sleeve Screws

- Roller Bearing

- T.E. Bearing Cover

- Ball Bearing

- Thrust Washer

- Thrust Nut

- Distance Piece

- Air Cock

- Stauffer

- Coupling Key

- Impeller Locking Device

- Impeller Locking Device